Advantages Description:

1. Size: thickness 5mm-200mm, to meet any needs of different industries

① The conventional thickness of traditional organic fiber board is 10-80mm. Too thin board has no strength and is fragile; too thick board cannot be dried thoroughly, and the middle part is easy to mold and deform, forming a "cotton core".

②Zhuqing inorganic board, with its high density and easy-drying characteristics, the thickness can be 5-200mm. On the basis of ensuring the high quality of the fiberboard, it can be extremely thin and thick without deformation, meeting the needs of different industries.

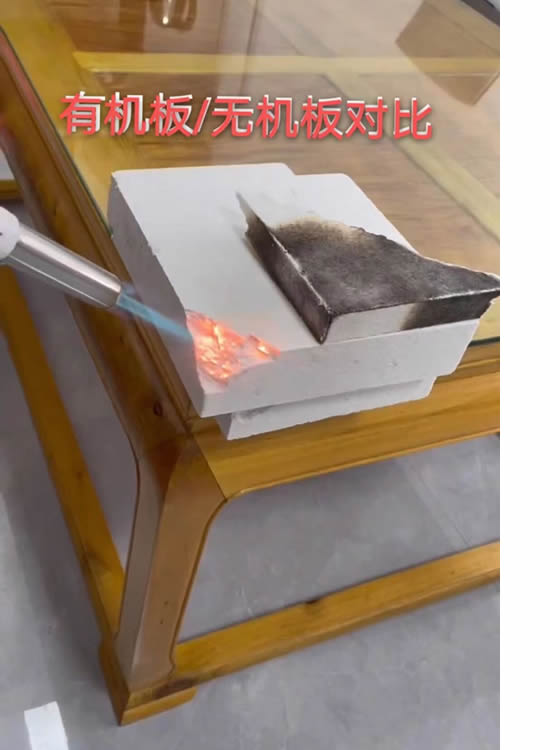

2. Organic matter: extremely low organic matter content, ≦1.5%

①Traditional organic fiberboard, with an organic matter content of 7-12%, is prone to moisture absorption and mildew, and the organic matter catches fire and smokes at high temperatures.

②Zhuqing inorganic board adopts high-quality inorganic glue, eliminates organic adhesives, achieves extremely low organic content, and avoids the problems of smoke, fire and peculiar smell in the use of fiberboard.

3. Thermal conductivity: extremely low

① The thermal conductivity of traditional organic fiberboard is ≦0.153% when the national standard stipulates that at 500°C. However, under long-term working temperature, the thermal conductivity will continue to rise from a low value, and the thermal insulation effect is poor.

②Zhuqing inorganic board, 900℃, ≦0.118%. Under the long-term working temperature, after rising to a certain temperature, the thermal conductivity will not change after maintaining a certain value.

(This comparison phenomenon is the result of the comparison test of Lucheng's customers in their own experimental furnaces)

4. Use: No smoke, no smell, no color change at high temperature. Good insulation effect and long service life

① Due to the high content of organic matter, the traditional organic board turns black and smokes at high temperature, and has a strong odor. After high temperature, the internal strength of fiberboard is very poor.

②Zhuqing inorganic board, because of its high-quality inorganic adhesive formula, does not need to be calcined, and can be formed at one time. It is truly smokeless, odorless and colorless under high temperature. And the heat preservation effect is remarkable, and the service life is much longer than the organic board.

(With regard to the service life and heat preservation effect, there have been two years of customer feedback results)

5. Shaped parts: high density, high strength, good toughness, can be used for any engraving

① Due to the characteristics of silica sol, traditional organic boards cannot form high-density fiberboards at one time. If you want to achieve high density, you must make it into a finished product and then immerse it in silica sol again. However, the surface of fiberboard is hard, and the internal strength cannot be achieved.

②Zhuqing inorganic board can be formed at one time, with a density of 400kg/m3 and above, and can be carved into special-shaped parts of any desired shape.

6. Production and environmental protection: no mildew, no waste water, no pollution, environmental protection and energy saving

①Modified starch is used in the production of traditional organic boards, which is prone to mildew; the discharge of waste water after the production is completed will cause inevitable pollution to the environment. The national environmental protection department has begun to gradually restrict this behavior.

②Zhuqing inorganic board production will not produce waste water, can be recycled, does not pollute the environment, truly achieve energy saving and environmental protection, and contribute to human progress.

At present, we have applied for patents, and the government department learned of this environmental protection behavior and began to fully support us, and will gradually implement it to the entire industry to replace the production pollution of traditional organic boards.

We hope that our company can make greater contributions to the development of environmental protection and energy saving in this industry !